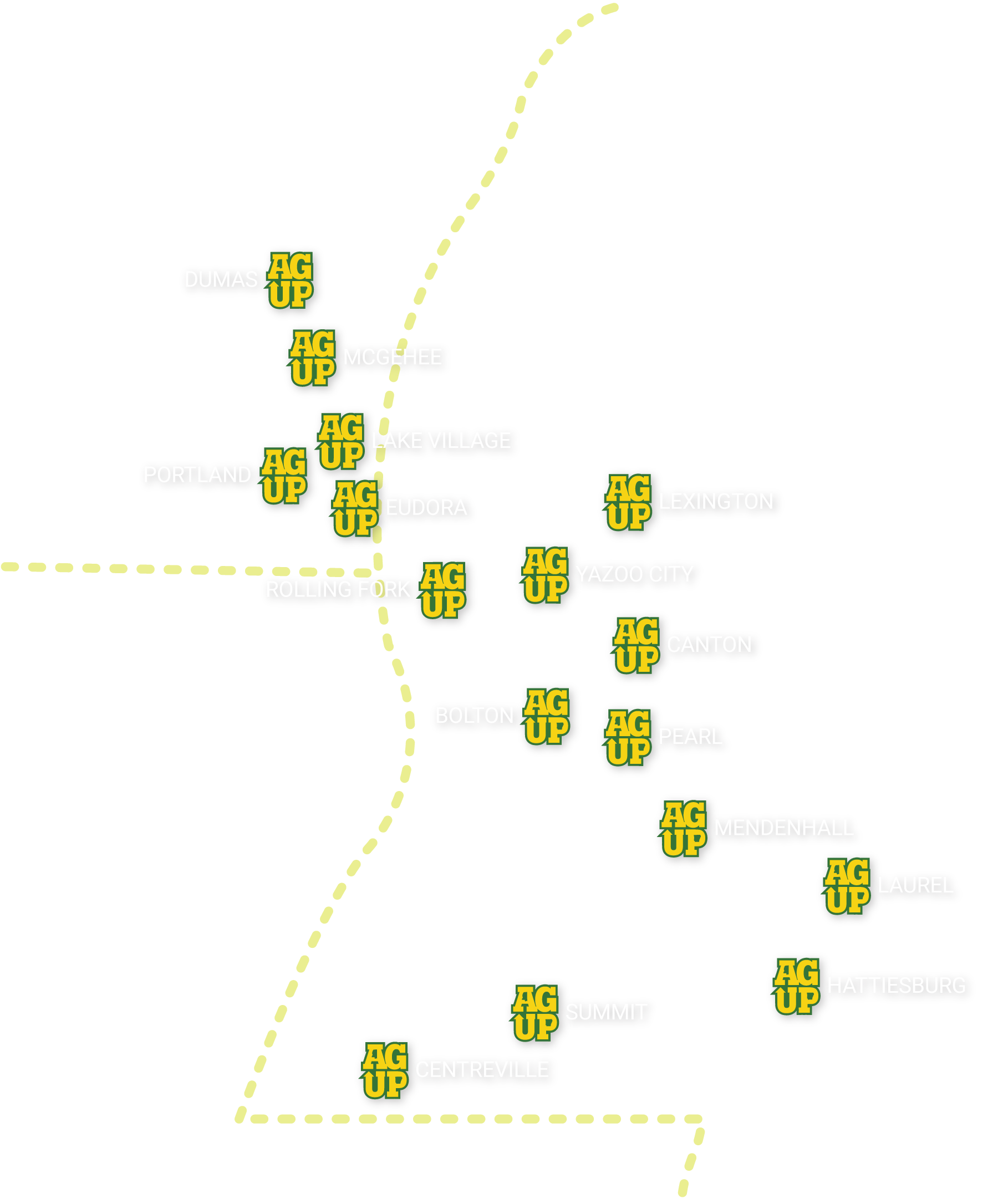

UP Your Career Here: AGUP.com/careers

UP Your Career Here: AGUP.com/careers

595 backhoe

Backhoe

- Full 180-degree swing provides increased productivity

- Quik-Tatch mounting for quick and easy mounting and dismounting

- Comfortable operator's area for increased productivity

View Product Brochure

Features

595 Backhoe

595 Backhoe

The 595 Backhoe swing system is a constant speed/constant torque system for good swing and smooth operation. The 180-degree swing allows trenching 90 degrees from the center of the tractor.

Double-acting swing cylinders are pinned directly to the swing frame, which gives a very compact swing system, eliminates complicated linkages and chains, and provides improved stability and extra torque for backfilling. Some competitors use a single cylinder and chain design that requires manual adjustment

Attaches solidly to 5 Series Tractors

Attaches solidly to 5 Series TractorsThe backhoe's subframe mounting bar fits into the rear mounting brackets that are attached to the tractor. This solid mount provides two valuable features:

- Stability by virtually eliminating vertical or side-to-side movement often found in some 3-point hitch backhoe mounts. The subframe design also positions the entire backhoe close to the tractor.

- Tractor chassis is protected by tying the respective tractor and the backhoe together as one. It also allows operators to take full advantage of the total weight transfer between backhoe stabilizers and loader buckets.

595 Backhoe

595 Backhoe Quick-pin mounting on a 5M Tractor

Quick-pin mounting on a 5M TractorThe front of the 595 Backhoe subframe is attached to the tractor with quick-pins for fast installation and removal. The backhoe's hydraulic hoses attach to the tractor hydraulic system (requires the power-beyond kit) with quick-couplers, further enhancing the ease of hookup and removal.

595 Backhoe on a 5M Tractor

595 Backhoe on a 5M Tractor

Two user-friendly levers are located on the console to control the boom lift, swing, dipperstick, and bucket. Updated control linkages require less operator effort and provide a better feel than cables, adding to operator comfort after digging for long hours.

A convenient location for storing swing and boom lock pins is provided on the operator station.

595 Backhoe operator platform

595 Backhoe operator platform

The operator station on the 595 Backhoe provides improved operator comfort with a flat, walk-through operator's area and large footrest. The operator area stays clean with a perforated floor design, which allows dirt and debris to drop through. A low-profile console allows an unobstructed view to the digging area.

The backhoe hydraulic valve is located under the operator's platform. This reduces noise and increases leg room and visibility for the optimal operator experience.

The backhoe seat is adjustable both vertically and horizontally, offering a comfortable position to a wide range of operators. When not in use, the seat pivots and locks up to help keep it clean and eliminate debris collecting on the cushion.

Entry and egress of the operator station is safe with a convenient grab rail. Large footrests with non-slip surfaces further ensure safety, while wide-stance stabilizers are angled rearward for easy operator entry.

Flip-over pads made of cast ductile iron allow a quick and easy conversion between field and street usage. The pads pivot to follow the contour of the terrain.

49 Backhoe

49 BackhoeBuckets are available in a variety of sizes to fit any job and provide superior productivity. The 49 Backhoe can be ordered with three heavy-duty buckets: 14-in., 18-in., and 24-in.

Replaceable bucket teeth are available.

595 Backhoe

595 BackhoeA four-bar linkage on the 595 Backhoe bucket cylinder provides 180-degree bucket curl to dig straight walls and prevent spills at loading height.

Specifications

Compare the specifications of up to 4 models

| Key Specs | 595-backhoe Current Model |

|---|---|

| Digging depth | 9 ft, 4 in. |

| SAE dipperstick digging force | 3065 lb |

| SAE bucket digging force | 5532 lb |

| Swing arc | 180 degree (angle) |

| Boom lift capacity | 905 lb |

| Transport height | 8 ft 2.6 m 8 in. |

| Stabilizers spread width, up | 5 ft 1.6 m 4 in. |

| Stabilizers spread width, down | 9 ft 2.9 m 8 in. |

| Bucket widths | 14 in. 18 in. 24 in. 36 in. 40 in. |

| Total weight | |

| Backhoe | |

| Swing arc | 180 degree (angle) |

| Bucket rotation | 180 degree (angle) |

| Boom lift capacity | 905 lb |

| SAE dipperstick digging force | 3065 lb |

| SAE bucket digging force | 5532 lb |

| Angle of departure | |

| Hydraulic relief setting | 2400 psi |

| Bucket control main relief valve pressure | |

| Dimensions | |

| Digging depth | 9 ft, 4 in. |

| Loading height (bucket at 60 degrees) | 8 ft 2.4 m 2 in. |

| Reach from center line of swing pivot | 12 ft 3.9 m 11 in. |

| Transport height | 8 ft 2.6 m 8 in. |

| Loading reach (bucket at 60 degrees) | 5 ft 1.5 m 1 in. |

| Transport overhang | 5 ft 1.5 m 1 in. |

| Undercut | 1 ft 335 mm 10 in. |

| Stabilizer type | Stabilizers spread width, up 5 ft 1.6 m 4 in. Stabilizers spread width, down 9 ft 2.9 m 8 in. Hydraulic |

| Weight | |

| Total | |

| With RSA side plate kit and 20-in. bucket | |

| With frame adapter and 24-in. bucket | |

| With medium frame adapter and 24-in. bucket | |

| With large frame adapter and 24-in. bucket | |

| With 0.4-m (16-in.) bucket | |

| Bucket | |

| Bucket widths | 14 in. 18 in. 24 in. 36 in. 40 in. |

Accessories and Attachments

Adapter Frame for Backhoe

Backhoes

Buckets

49 Backhoe

49 BackhoeBuckets are available in a variety of sizes to fit any job and provide superior productivity. The 49 Backhoe can be ordered with three heavy-duty buckets: 14-in., 18-in., and 24-in.

Replaceable bucket teeth are available.

49 Backhoe

49 BackhoeBuckets are available in a variety of sizes to fit any job and provide superior productivity. The 49 Backhoe can be ordered with three heavy-duty buckets: 14-in., 18-in., and 24-in.

Replaceable bucket teeth are available.

49 Backhoe

49 BackhoeBuckets are available in a variety of sizes to fit any job and provide superior productivity. The 49 Backhoe can be ordered with three heavy-duty buckets: 14-in., 18-in., and 24-in.

Replaceable bucket teeth are available.

Hydraulics

Power Beyond Coupler Kit - LVB25367

This kit offers continuous hydraulic flow for hydraulic motor applications. The tractor must be equipped with at least one selective control valve for installation, and the triple rear deluxe hydraulic control valve is recommended.

This kit offers continuous hydraulic flow to be used with implements that already have a flow control device. The power beyond coupler kit is required for backhoe installation.

Miscellaneous

Motor control kit (Power Beyond) - BSJ10091

Rubber street pads on 48 Backhoe

Rubber street pads on 48 BackhoeRubber stabilizer pads are available for those who operate their backhoe on hard surfaces. The rubber pads minimize scratching and damages to floor surfaces and help when skidding of the backhoe is a problem.

The pads can be ordered as optional equipment and easily attach to the standard claw-type stabilizer pad.