115 flail shredder

Drawn Flail Shredder

- Heavy-duty gearbox

- Steel rotor bearings

- Convenient rear grease fittings

- Square rotor designed for superior strength

View Product Brochure

Features

Drawn tractor hookup

Drawn tractor hookup

Rubber deflectors

Rubber deflectors

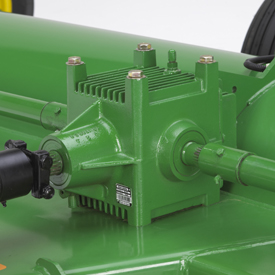

Gearbox

GearboxA heavy-duty gearbox transfers power to the power-band drive belts through cross shafts with intermediate bearing supports:

- Gearbox has a constant-duty rating of 150 hp and a maximum rating of 225 hp.

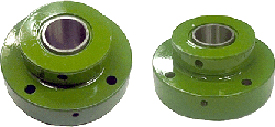

Rotor bearings

Rotor bearingsThe rotor bearings are now made of steel and have a three-lip seal to keep the dirt out and increase the life of the bearings.

The side and center bearings now have guards in order to avoid leaks and dust, increasing the life of the bearings.

Specifications

Compare the specifications of up to 4 models

| Power requirements | 115-flail-shredder Current Model |

|---|---|

| Tractor PTO hp range | 67-149 kW 90-200 hp |

| Tractor RPM | 1,000 rpm |

| Gear case | |

| Knives | |

| Number of knives | 120 |

| Knife dimensions | 7.87 x 63.5 x 143 mm 0.31 x 2.5 x 5.63 in. |

| Knife mounting system | |

| Type | Heat-treated side slice |

| Knives overlap | |

| Tip speed | 171 km/h 106 mph |

| Rotor | |

| Rotor speed | 1,500 rpm |

| Rotor diameter | 139.7 mm 5.5 in. |

| Rotor bearing | Sealed, self-aligning, piloted housing, auxiliary |

| Bearing size | 41.28 mm 1.625 in. |

| Drivetrain | |

| Belts | Power band, triple 5VX |

| PTO drivelines | |

| Mainframe | |

| Hitch | Drawn |

| Hood thickness | 6.35 mm 0.25 in. |

| Safety deflector | Yes |

| Gauge wheels | 4 infinitely adjustable |

| Warning lights | |

| Cutting capacity | |

| Cutting width | 4.6 m 15 ft |

| Cutting height | 7.6 to 25.4 cm 3 to 10 in. |

| Dimensions | |

| Transport width | 2.39 m 7.83 ft |

| Transport length | 5.82 m 19.08 ft |

| Weight | 1,497 kg 3,300 lb |

| Optional equipment | |

| Easy transport | |

| Constant velocity joint driveline | Yes |

| Skid shoes |

Accessories and Attachments

Miscellaneous

Deflectors - Rubber - BP18083

Steel deflectors

Steel deflectors Rubber deflectors

Rubber deflectorsDeflectors can be used on the front of the shredder to prevent cut material from being thrown forward. Rubber deflectors are recommended when shredding in rocky areas.

Driveline with Overrunning Clutch and Constant Velocity Joint, 1-3/4 In. Drive - AP40461

Driveline with Overrunning Clutch and Constant Velocity Joint, 1-3/8 In. Drive - AP40459

Driveline with Overrunning Clutch, 1-3/4 In. Drive - AP40460

Additional gauge wheel

Additional gauge wheel

Additional gauge wheels can be ordered, if needed, for improved cutting performance.

Hydraulic Cylinder (3X8) with Hoses - BP16519

Lateral Skid Plate - AP40006

Weed Separator

Center divider

Center divider

The center divider minimizes the center strip of uncut material when clipping grass, idle acres, or non-row-crop crops.

This bundle is for use on all shredders with the following serial numbers:

- 115 Flail Shredder (serial numbers 002485 and above)

- 118 Flail Shredder (serial numbers 002072 and above)

- 120 Flail Shredder (serial numbers 002258 and above)

NOTE: Previous machines did not have center-cut knives. To install, order them from Parts.