UP Your Career Here: AGUP.com/careers

UP Your Career Here: AGUP.com/careers

388 rear mount mower conditioner

Rear Mount Mower-Conditioner

- Adjust windrow width

- Rotary disc cutterbar

- Simple to operate platform controls

View Product Brochure

Features

Transport position

Transport position Operating position

Operating positionThe 388 Twin Rear-Mounted Mower Conditioner is matched with a 131 Front-Mounted Mower-Conditioner to make what is commonly called a Triple-Mounted Mower-Conditioner (TMMC). This combination cuts nearly 8.73 m (28 ft, 8 in.) but can easily be converted to a narrow transport width of 3.1 m (10 ft, 2 in.).

131 Mower-Conditioner transport position

131 Mower-Conditioner transport position Transport lock for 131 Mower-Conditioner

Transport lock for 131 Mower-ConditionerTo prepare for transporting, the side curtains of the 131 Front-Mounted Mower-Conditioner are unlocked and folded into the transport position. This will reduce the overall width during transport. The transport lock lever on the 131 Front-Mounted Mower-Conditioner is engaged so that side-to-side oscillation during transport is eliminated.

388 Mower-Conditioner side curtain lock

388 Mower-Conditioner side curtain lock Side curtain support shown in transport position

Side curtain support shown in transport positionThe side curtains are unlocked and pinned to reduce the overall transport height of the TMMC. The side curtain support provides rigidity to the side curtains during cutting and is folded down in transport to reduce the overall height.

Zone 2 active

Zone 2 active Zone 1 active

Zone 1 activeUsing the control panel configured to headland turn (switch in yellow circle moved to RH, Zone 2 switch centered), the operator uses the tractor hydraulics to raise the platforms. The mower-conditioner frame should be centered in preparation for transport.

- Move switch to activate Zone 1

- Hold switch up to fold mower-conditioner while activating the tractor selective control valve (SCV)

- When completely folded, spring controlled locks secure the mower-condtioner in the transport position

Rear three-point hitch may be adjusted, as necessary, to assure the overall height of the mower-conditioner does not exceed 4.0 m (13 ft, 1 in.).

A spring-loaded safety lock secures the mower-conditioner in the raised position.

To prepare for field operation, the rope connected to the safety lock on the 388 Twin Rear-Mounted Mower-Conditioner is held while the platforms are partially lowered (rope can be released as soon as mower-conditioner is unlatched), using the control panel and tractor SCV.

The balance of the procedure above is reversed to continue on to field operation.

Left-hand accumulator pressure gauge

Left-hand accumulator pressure gauge  Right-hand and left-hand accumulators

Right-hand and left-hand accumulatorsFlotation is controlled by accumulators on both the right-hand and left-hand cutting platforms. The easy to read gauges (one for each cutting platform) enable the operator to easily adjust the float pressure to the desired level.

A ball valve by the pressure gauge is opened and by using the control panel mounted in the tractor and the tractor selective control valve (SCV), the pressure can be adjusted to meet varying ground or crop conditions.

Control for adjusting flotation (yellow circle)

Control for adjusting flotation (yellow circle)

The control panel is used to adjust flotation of both the rear cutting platforms as well as the 131 Front-Mounted Mower-Conditioner.

- The third switch from the left is moved to the left to activate the features on the left side of the control panel

- Platforms are placed in cutting position

- Ball valve by pressure gauge is opened

- Open both valves on 388 Twin Rear-Mounted Mower-Conditoner to adjust float pressure to the same setting

- Right-hand and left-hand platforms can be adjusted separately if required

- Open valve by gauge on 131 Front-Mounted Mower-Conditoner to adjust float pressure on front unit

- Hold switch (yellow circle) up to adjust 131 Front-Mounted Mower-Conditioner or hold down to adjust 388 Twin Rear-Mounted Mower-Conditioner

- Activate tractor selective control valve (SCV) to reach desired setting

- Release switch

- Close appropriate ball valves

Impeller conditioner

Impeller conditioner

Each cutting unit is equipped with 54 free-swinging, steel impeller tines. This John Deere conditioner provides excellent conditioning performance and fluffy windrows.

Impeller conditioning is standard equipment on all John Deere mower-conditioners.

Proper conditioning in a wide range of crops can be achieved when the conditioner is properly adjusted.

The impeller conditioner works well in legumes, especially alfalfa and most all-grass crops. Impeller conditioners are not recommended for thick-stemmed or cane-type crops, such as sudan or sudex, or crops over 5-ft tall.

How an impeller conditioner works:

Impeller conditioning

Impeller conditioning

- As hay is cut by rotating knives, tines pick up the plants and carry them through the machine: Tines are free swinging to reduce damage to the conditioner if rocks or other solid objects are struck.

- As the plant passes through, it rubs against the conditioning hood and other plants: Scuffing action removes the waxy surface from the stem of the plant to allow faster evaporation of moisture. The hood is easily adjustable to increase or decrease the conditioning effect.

- The pivot point for the conditioning hood is also adjustable to provide a wider range of conditioning intensity.

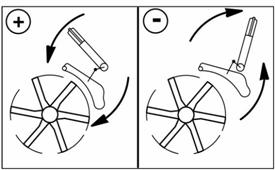

Adjusting impeller speed (shield removed for illustration)

Adjusting impeller speed (shield removed for illustration)

The speed at which the tines rotate will also affect the degree of conditioning. Two impeller speeds can be achieved by interchanging the upper sheave and the lower sheave.

- With the sheaves in the position shown, the impeller turns at 888 rpm; this is ideal for grasses.

- If the sheaves are reversed (arrow), the impeller turns at 615 rpm; this is ideal for legume crops.

- Impeller speed on both cutting units should be matched.

Windrows to match your needs

Windrows to match your needs

Forming shields are easily adjusted to control material flow. This allows the operator to match the windrow width to harvesting requirements.

Windrow forming shields (rear curtain raised for visibility)

Windrow forming shields (rear curtain raised for visibility) Adjustment handle (arrow)

Adjustment handle (arrow)The forming shields are easily adjusted to match harvest requirements. No tools are required to adjust the forming shields. Windrow width on each unit can be adjusted from 1.2 to 2.5 m (3 ft, 11 in. to 8 ft, 2 in.).

A widespread kit is available as a field-installed bundle. The bundle consists of vanes that are installed behind the conditioning hood. The windrow width when using the widespread kit can be adjusted to be approximately the same as the cutting width of the platform.

388 Twin Rear-Mounted Mower-Conditioner

388 Twin Rear-Mounted Mower-Conditioner Cutterbar cutaway drawing

Cutterbar cutaway drawingPower is transmitted from the 1000-rpm tractor (1-3/4-in.) PTO through a central gearcase to the twin rear-mounted cutterbars.

- Each cutterbar is protected by a slip clutch and overrunning clutch

- The cutterbar is securely mounted within the frame for strength and durability

- Power is transmitted to the rotary disks through fully enclosed gears, running in oil, for quiet, smooth, reliable operation

- The high-speed rotary disks cut in the toughest conditions. The disks rotate at 2986 rpm

- Low-profile design enables cutting close to the ground at a flat angle helping prevent damage to the disks and knives

- Cutting height is adjusted by changing cutting angle

- Pinion gear is easily removed from the top of the cutterbar for service

- Idler gears can be removed from access area after removal of pinion gear

- Idler gears can be removed from access area after removal of pinion gear

Control panel

Control panel

The simple to operate control panel enables the operator to easily operate all of the hydraulic functions of the 388 Twin Rear-Mounted Mower-Conditioner.

Features/functions of the control panel include:

- On/off push-button switch with indicator light

- Reverse polarity indicator light

- Folding 388 Twin Rear-Mounted Mower-Conditioner into transport position

- Adjusting floatation of 131 Front-Mounted Mower-Conditioner

- Adjusting floatation of 388 Twin Rear-Mounted Mower-Conditioner

- Zone selection switch

- Headland turn selection switch

Control panel zone selection

Control panel zone selectionWith the power switch on, the zone selector switch (yellow circle) determines which functions are active by powering either Zone 1 or Zone 2.

Zone 1 active

Zone 1 active

With the zone selector switch moved to activate Zone 1 the operator can fold the 388 Twin Rear-Mounted Mower-Conditioner into transport position or adjust the cutterbar flotation on either the front or rear cutterbars.

- The 388 Twin Rear-Mounted Mower-Conditioner can only be raised into the transport position after turning off the rear PTO and waiting for all components to stop moving. The rear mower-condioners must also be moved into the headland position prior to folding for transport.

- The left-hand switch in zone 1 is used to fold and unfold the mower-conditioner.

- The switch must be held while activating the proper tractor selective control valve (SCV) to fold or unfold the mower-conditioner.

- It is a momentary switch and will return to its neutral position when released.

- A mechanical lock secures the platforms in the transport position.

- The switch must be held while activating the proper tractor selective control valve (SCV) to fold or unfold the mower-conditioner.

- The right-hand switch in zone 1 is used to adjust cutterbar flotation on the front and rear mower-conditioners .

- A hydraulic line is routed from the 131 Front-Mounted Mower-Conditioner to connect to the 388 Twin Rear-Mounted Mower-Conditioner.

- The switch is held upward to adjust the flotation of the 131 Front-Mounted Mower-Conditioner.

- The switch is held downward to adjust the flotation of the 388 Twin Rear-Mounted Mower-Conditioner.

- Ball valve on respective units must be opened to adjust pressure and closed when complete

Zone 2 active

Zone 2 active

Zone 2 is the primary setting for field operation. The three-position switch in Zone 2 is used to select the headland turn or working position of the rear cutting units. The position of the switch will determine which cutting platform or both will be raised

- Center position – using the tractor SCV, both cutting platforms will be raised or lowered when making a headland turn

- Left position – the left-hand cutting platform will remain raised when reentering the crop (used to avoid recutting windrows)

- Right position - the right-hand cutting platform will remain raised when reentering the crop (used to avoid recutting windrows)

Specifications

| Power requirements | 388-rear-mount-mower-conditioner Current Model |

|---|---|

| PTO speed | 1,000 rpm |

| HP 540 rpm PTO | |

| HP 1000 rpm 1-3/8 in. PTO | |

| HP 1000 rpm 1-3/4 in. PTO | With 131 Front-Mounted Mower-Conditioner: 147 kW 190 hp |

| Powerline type | |

| Hydraulic pressure required | |

| Cutterbar | |

| Type | Rotary |

| Cutting width | With 131 Front Mounted Mower-Conditioner: 8.7 m 28.6 ft |

| Cutting height | 3-8 cm 1.2-3.2 in. |

| Number of disks | 8 per unit |

| Number of knives | 16 per unit |

| Disk speed | 2,986 rpm |

| Knife tip speed | |

| Disk drive | Gear |

| Lubrication | GL-5 gear lubricant |

| Oil reservoir capacity | 2.25 L 0.59 U.S. gal. |

| Cutterbar oil check | Fill plug |

| Cutterbar angle | Adjustable |

| Angle adjustment | Tractor center link |

| Angle range | |

| Cutterbar protection | Shear shaft |

| Adjustable gauge shoes | |

| Conditioner | |

| Impeller | Width 264 cm 104 in.Number of V-tines 54 per unitNumber of speeds TwoDrive Belt and sheavesConditioner hood Adjustable |

| Rolls | |

| Tractor hookup | |

| Standard hitch | Tractor 3-point |

| Ball joint equal angle hitch | |

| Rockshaft swivel hitch | |

| Drawbar swivel hitch | |

| Dimensions | |

| Overall width | Transport 3.1 m 10.1 ft |

| Overall length | |

| Weight | With impeller conditioner 2,986 kg 6,583 lb |

| Standard tires | |

| General | |

| Are wrenches required for adjusting? | Float Yes |