615p belt pickup platform

Belt Pickup Platform

- Hydraulic adjustable windscreen maximizes control

- Dual-belt draper pickup

- Steel auger fingers

- Fixed gauge wheels reduce width of platform

View Product Brochure

Features

615P suspension system

615P suspension system

The exclusive FieldGlide suspension system features an adjustable air spring and heavy-duty hydraulic shock design to dampen movement during field operation, allowing the operator to increase harvesting speed. Once set, the air springs do not need adjustment during the season.

Feature benefit:

- Improves windrow harvesting performance

- Harvest at faster speeds

- No tools needed

Functionality

Adjustment of the air springs requires no tools and is simple compared to other belt pickup suspensions. Adjust the air springs according to instructions located on the belt pickup side sheets.

615P hydraulic windscreen

615P hydraulic windscreen

The hydraulic windscreen on the 615P allows the operator to maximize productivity by controlling the crop flow in changing windrow conditions.

Feature benefit:

- Adjustments made from the cab

- Control crop flow in changing windrow conditions

Functionality

Manual tilt adjustment for windscreen

Manual tilt adjustment for windscreen

The hydraulic windscreen utilizes double-acting cylinders which react quicker in maximizing the control of the crop. The windscreen is controlled by the fore-and-aft control on the combine hydro handle. A benefit is the header backshaft speed can be controlled independently of the windscreen allowing for increased belt pickup, and auger/feederhouse chain speed for tough windrow conditions.

Crop transition on 615P

Crop transition on 615P

The 615P features a dual-belt draper to enhance material flow into the combine when harvesting windrows.

Feature benefit:

- Smooth material flow into the auger

- Increased material handling capacity

- Allows crop to fall from the pickup belts

Functionality

The transfer belts move crop under the 66-cm (26-in.) diameter auger. This provides significant material handling advantages in large/dense windrows.

615P

615PThe 615P features 4.5-m (14.8-ft) wide belts for enhanced belt tracking with reduced seed loss.

Feature benefit:

- Eliminates the need for a complicated center-support roller

- Reduces seed loss

- Improved belt tracking

Functionality

Connectors between belts improve belt-drive capacity in tough windrow conditions without the need for a center support on the drive rollers. This design eliminates roller flanges which would create a gap between belts and could result in crop losses. The heavy-duty 615P belts are designed for maximum wear life.

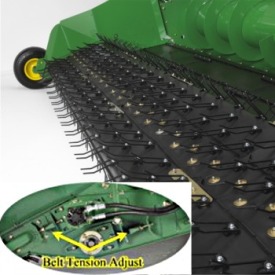

615P belt tensioning

615P belt tensioning

The 615P features a belt tensioning system for extended belt and roller life.

Feature benefit:

- Belts are evenly tensioned for uniformed loading

- Easy adjustment that requires minimal tools

- Minimizes seed loss

Specifications

Compare the specifications of up to 4 models

| Key Specs | 615p-belt-pickup-platform Current Model |

|---|---|

| Total picking width | 4.55 m 14.9 ft |

| Header height control | Hydraulic |

| Number of fingers per belt | 84 |

| Auger diameter | 66 cm 26 in. |

| Auger fingers | Heavy-duty and round with breakaway notch Diameter: 15.9 mm 0.625 in. |

| Header | |

| Transport widths | 5.35 m 17.5 ft |

| Header height control | Hydraulic |

| Pickup Belts | |

| Width of belts | 1.13 m 3.7 ft |

| Number of belts per pickup | Four picking, four transfer |

| Total picking width | 4.55 m 14.9 ft |

| Operating speed of belts | 3-150 m/min 10-475 fpm |

| Number of rollers | Two picking, two transfer |

| Pickup Fingers | |

| Type | Plastic |

| Number of fingers per belt | 84 |

| Auger | |

| Float range | 57 mm 2.25 in. |

| Diameter | 66 cm 26 in. |

| Auger fingers | Heavy-duty and round with breakaway notch Diameter: 15.9 mm 0.625 in. |

| Number of auger fingers | 19 STS, maximum 22 |

| Auger finger pattern | In-line, retracting |

| Finger reach | 152 mm 6 in. |

| Operating speed | At 520 feederhouse speed: 180 rpm |

| Tires | |

| Weight | |