706c corn head

Corn Head

- Gathering chains designed for increased life

- Knife stalk rolls result in better stalk control

- AutoTrac™ RowSense™

- Single-point latching system is fast and easy

View Product Brochure

Features

Customers have asked for stalk rolls to appropriately size residue for their operation while managing power and overall header weight.

John Deere offers RowMax stalk rolls to address customer needs around residue, power, and weight for their front-end equipment.

RowMax stalk roll features and benefits:

- RowMax stalk rolls can improve wear life by 25 to 30 percent compared to the 600C base stalk rolls.

- Three stalk roll options allow customers to select the appropriate length of corn stalk residue.

- To provide high performance during harvest, RowMax stalk rolls are designed with reduced power and fuel consumption in mind.

- RowMax Chopping Stalk Roll drops stalk residue on top of the row for improved planting performance for no-till and strip-till customers the following season. Additionally, the chopping stalk roll blossoms the top of the stalk for reduced tire and track damage.

Stalk residue dropped on top of the row

Stalk residue dropped on top of the row Top of the stalk is blossomed

Top of the stalk is blossomedRowMax stalk roll details:

- The stalk rolls are manufactured from highly durable austempered ductile iron material with an added wear coating for increased wear life.

- The full-length blades provide total crop contact for appropriate sizing and cutting action from front to back.

- Stalk roll tip speed compared to gathering chain speed is optimized to reduce material-other-than-grain (MOG) intake and increase overall capacity while minimizing losses.

- Enclosed chain drives gathering chains and stalk rolls for each row to provide robust durability and uninterrupted harvesting.

- Single-piece cast knife roll design provides excellent serviceability when replacement is required.

Row-unit

Row-unit Single-piece cast knife roll

Single-piece cast knife rollChoosing the correct RowMax stalk roll

| Stalk rolls without StalkMaster™ corn heads | RowMax Opposed | RowMax Intermeshing | RowMax Chopping |

| Knife alignment |  |  |  |

| Residue size | Good | Good | Better |

| Residue breakdown | Fast | Faster | Fastest |

| Soil warm up/dry down | Fast | Faster | Fastest |

| Wear life | Better | Better | Best |

| Row unit power consumption | Best | Better | Better |

| Fuel consumption | Best | Better | Good |

| Trash intake | Best | Better | Better |

| Dry stalks | Best | Good | Good |

| Wet stalks | Best | Better | Better |

| Down corn | Best | Good | Good |

| Weight for two stalk rolls | 17.2 kg (38 lb) | 18.1 kg (40 lb) | 19.5 kg (43 lb) |

| StalkMaster with RowMax opposed stalk roll | |||

| Residue size | Best | ||

| Row unit power consumption vs. opposed without StalkMaster | Good | ||

| Weight | Additional 19.1 kg (42 lb) per row for StalkMaster components | ||

| General stalk roll parts information | |||

| Number of knives | 8 | 6 | 10 |

| Aftermarket part numbers* (left hand) | HXE110671 | HXE110675 | HXE141569 |

| Aftermarket part numbers* (right hand) | HXE110672 | HXE110676 | HXE141570 |

| Compatibility | Model year 2012 and newer 600C/600FC and 700C/700FC for StalkMaster and non StalkMaster row units; factory-installed option code for model year 2020 Corn Heads | ||

*NOTE: Part numbers are subject to change. Please check the parts order before completing the transaction.

The 700C/FC Corn Head RowMax row-unit provides customers increased durability and longer wear life. RowMax row-units include updates to gathering chains, gathering chain sprockets, chain guides, and stalk rolls. These improvements extend the life of the corn head for lower ownership cost.

Feature benefit:

- Increased wear life of row-unit gathering chains and sprockets by 50 percent due to solid alloy pin bushings and increased number of sprocket teeth

- Increased wear life of stalk rolls up to 30 percent with an improved wear coating

- Maintain corn head performance durability with an increase in stalk roll material hardness

RowMax row-unit

RowMax row-unit Gathering chain and sprocket

Gathering chain and sprocketFunctionality:

To extend the life of the corn head, the RowMax row-unit increases the number of sprocket teeth on gathering chains from six teeth to eight teeth. The gathering chain has an additional 12 links and an anti-bend back feature on the chain lug. Gathering chain wear is reduced by using a solid alloy bushing.

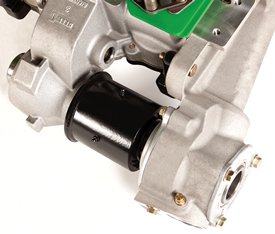

StalkMaster row-unit

StalkMaster row-unitAvailable as an option, StalkMaster provides ultimate stalk sizing by processing stalks smaller than stalk rolls allowing the operator to potentially eliminate second-pass operations, saving time, fuel, labor, and additional operating costs.

Feature benefit:

- Consistent sizing of corn stalks to speed up decomposition and provide soil protection from blowing wind and water runoff

- StalkMaster can be equipped with either intermeshing, opposed, or chopping stalk rolls

- Ultimate flexibility to chop or not chop when desired through a quick, no-tools-required disconnect feature

Functionality

StalkMaster blades

StalkMaster bladesEach StalkMaster row-unit gearcase is equipped with two heat-treated and wear-coated rotating blades positioned below the stalk rolls. The blades can be reversed to extend their wear life. These blades cut stalk to size and distribute residue evenly throughout the row. If the blades encounter an obstruction they will swing backward, avoiding damage and interruption to harvest.

StalkMaster disconnect feature

StalkMaster disconnect featureThe StalkMaster row-unit gearcase feature a no-tools-required disconnect. Each row has a lever on the right side of the gearcase to turn the function on or off in a matter of minutes if desired, allowing for lower fuel consumption.

StalkMaster gearcase

StalkMaster gearcaseA heavy-duty slip-clutch design protects the row-unit gearcase and the StalkMaster lower unit gearcase.

712C right-hand side and drive shaft

712C right-hand side and drive shaftThe gathering chains and stalk rolls for each row are enclosed to provide robust durability. Heavy-duty bearings along with O-ring seals improve serviceability.

Larger sprockets and chain

Larger sprockets and chainA continuous-loop chain allows higher loads and longer life by eliminating all connector links and half links. The large-diameter sprockets along with a large 38-mm (1.50-in.) transverse hex back shaft and row-unit shaft provide improved sprocket and chain.

Telescoping drive shaft

Telescoping drive shaftA telescoping drive shaft mounts to the splined feederhouse back shaft on all 50, 60, 70, W-, T-, C-, and S-Series Combines.

The coupler features an 8-degree index, allowing the customer to match the drive shaft splines without rotating the platform feederhouse.

Telescoping drive shafts can be retrofitted to earlier 90 Series and 40 Series Corn Heads.

Rubberized curtains

Rubberized curtains Steel-protective shield

Steel-protective shieldStalkMaster row units feature side- and rear-mounted rubberized curtains to optimize residue distribution. The right-hand side of the head has an additional shield to protect customers from protruding blades.

Feelers keep the combine on the row

Feelers keep the combine on the rowAutoTrac RowSense, an innovative global positioning system (GPS) steering system, reduces overlap and fatigue during harvest.

Feature benefit:

- Continue harvesting in down crop and dusty conditions

- Increases acre-per-hour potential and reduce grain loss

- Enhances operator comfort while reducing stress

Functionality

StarFire™ position receiver picks up signal

StarFire™ position receiver picks up signalSpecifications

Compare the specifications of up to 4 models

| Key Specs | 706c-corn-head Current Model |

|---|---|

| Approximate overall width | 4.6 m 15.1 ft |

| Row spacings | 69.9, 74.9, 76.2, 91.4, or 96.5 cm 27.5, 29.5, 30, 36, or 38 in. |

| Deck plate adjustment | Hydraulic adjustment |

| Gatherer chain adjustment | Spring loaded, self-adjusting |

| Gatherer chains | Heavy-duty, 620, endless steel roller chain with chromed pins (no master connecting link) |

| Corn Head | |

| Gatherer points | Four-position, low-profile floating type hinged above gatherer chains |

| Center and outer gatherers | Hinged, quickly removable |

| Gatherer chains | Heavy-duty, 620, endless steel roller chain with chromed pins (no master connecting link) |

| Minimum clearance between gatherer chains and ground | 32 mm 1.25 in. |

| Row unit drive | Enclosed, submerged-in-lubricant gearbox, driven by single input hexagon shaft |

| Gatherer chain adjustment | Spring loaded, self-adjusting |

| Stalk rolls | Opposed knife, intermeshing knife, opposed fluted (two per row-unit) |

| Deck plate adjustment | Hydraulic adjustment |

| Slip clutch | One per row-unit plus auger drive |

| Trash knives | Full-length, one-piece, heat-treated steel |

| Chopping options | |

| Dimensions | |

| Approximate overall width | Points in operating position (lowered) 3 m 10 ft Points folded up (service position) 2.7 m 9 ft 4.6 m 15.1 ft |

| Approximate shipping weight (includes shipping skid) | 1985 kg 4377 lb |

| Row spacings | 69.9, 74.9, 76.2, 91.4, or 96.5 cm 27.5, 29.5, 30, 36, or 38 in. |

| Standard weight |