greenstar 3 2630

Display

- Control and monitor your work by creating multiple run pages and easily switching between them to see what you need to see

- Reduce your display investment by moving the display between machines and use it where you need it when you need it

- Use the precision ag applications you need on your farm by purchasing one-time software license activations

View Product Brochure

Features

The John Deere GreenStar™ 3 2630 Display is a 26-cm (10.4-in.) color display that features a full-color touchscreen for controlling a variety of precision applications, machines, and implements.

The GreenStar 3 2630 Display also allows operators to set up multiple home pages and navigate to each home page easily and efficiently, all while other applications are in use. The GreenStar 3 2630 Display is specifically designed for producers who desire maximum efficiency, productivity, and premium features outlined below.

Remote Display Access (RDA)

As the number of precision ag products continues to increase and more technology becomes integrated into ag equipment, along with varying operator skills in the cab, it is necessary for producers to be able to remotely manage operations and dealers to be able to provide remote support.

From an internet-connected device, users with RDA and JDLink™ communication services can help operators using the GreenStar 3 2630 Display.

From an internet-connected device, users with RDA can view the operator’s GreenStar 3 2630 Display screen. This functionality enables the RDA user to identify a problem and help the operator navigate through the steps needed to resolve the issue.

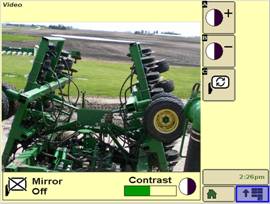

Video capability

Camera

Camera Video displayed

Video displayedThe GreenStar 3 2630 Display can support up to three video inputs for those who want more visibility when operating large machinery. Utilizing an Ethernet connection limits capacity to a single video input. Video can be viewed while operating machinery directly on the GreenStar 3 2630 Display.

The video images can be included in a loop that automatically cycles through each video input. Video can also be set as a quarter of a home page screen.

The GreenStar 3 2630 is compatible with the following camera signal types:

- National Television System Committee (NTSC)

NTSC is the North American standard for all cameras.

ISOBUS capable

The GreenStar 3 2630 is an ISOBUS virtual terminal 3 (VT3) capable display. ISOBUS VT3 allows the display to control ISOBUS-compatible implements and controllers. This compatibility allows the GreenStar 3 2630 Display to be used in a variety of applications and, in many cases, reduces the number of displays in the cab.

The GreenStar 3 2630 Display can also manage variable-rate applications and section control with non-John Deere implements, thanks to its ISOBUS compatibility.

Visibility

GreenStar 3 2630 and GreenStar 2 2600 Displays

GreenStar 3 2630 and GreenStar 2 2600 Displays

The GreenStar 3 2630 Display provides the same screen size and it features:

- A 50 percent smaller bezel allowing for better visibility in the cab

- A 30 percent brighter screen

Hardware

USB compatible

USB compatible

USB compatible

- The GreenStar 3 2630 Display has an easy-to-find storage device, making it simple to transfer information like prescriptions to the display or pulling documented maps from the display to use in APEX™ farm management software.

USB requirements

Most USB memory storage devices are compatible with John Deere displays. Below are the USB flash drive requirements:

- Format - Windows® FAT or FAT32 system

- Capacity - No specific limits to the memory capacity of the drive

- Connectivity - USB 2.0

- Maximum dimensions - 9.2-mm thick by 21.7-mm (0.36-in. by 0.85-in.) wide

- Orderable – From a John Deere dealer

Memory

The GreenStar 3 2630 Display has:

- RAM memory that allows the display to refresh quickly when multiple applications are in use.

- Flash memory, or internal memory, eliminating the need for flash drives on the display.

Processor size

The GreenStar 3 2630 Display has a fast, powerful processor that helps reduce display lockups.

Access manager can be used to prevent operators from changing settings in the field by locking specific settings. These settings are determined by the producer and can be password protected. Access manager allows for less operator error while being more productive in the field.

Layout manager

Layout manager allows operators to configure home pages on the GreenStar 3 2630 Display in the format desired, displaying the information that is essential to them. Layout manager also allows operators to page through other screens by simply selecting the home page icon.

Standby mode

Standby mode

Standby mode

Standby mode allows operators to dim the display while driving between fields or at night. The standby softkey is displayed when the menu is selected.

Standby mode also eliminates non-critical alarms and other warnings that appear on screen while in transport, but still alerts operators of any critical warning.

Operators can exit standby mode by simply touching the screen.

Field locator

The GreenStar 3 2630 Display automatically recognizes what field it is in during machine startup to ensure data is being documented to the correct location.

The field locator notifies operators when they have left the field and helps operators select the correct field by using global positioning system (GPS) data. Touching the map screen allows operators to search for a new field.

Machine and Implement Control

The GreenStar 3 2630 Display allows machine and implement control by interfacing with John Deere controllers. SprayStar™ system, SpreadStar™ system, SeedStar™ system, GreenStar Rate Controller, and third-party controllers can all interface with the GS3 2630 Display.

The GreenStar 3 2630 Display along with these controllers can control seeding and application rates, as well as document those rates, all while providing a coverage map showing the area applied. All data is collected and can later be unloaded in APEX, where it can be shown in the form of maps and reports.

Transfer data

The GreenStar 3 2630 Display is capable of transferring data multiple ways. Utilize Wireless Data Transfer (WDT) to automatically send data to the John Deere Operations Center or utilize a USB to manually move data between displays. Guidance lines can be transferred between GreenStar 3 2630 Displays via USB without the need to import the setup profile through APEX. Simply export the profile with desired guidance lines from one GreenStar 3 2630 Display to a USB. Then insert the USB into a different GreenStar 3 2630 Display to select and import the desired guidance lines.

Windows is a trademark of Microsoft Corporation.

With growing costs of seed, fertilizers, and agrochemicals, the interest in site-specific application is rising tremendously. The GreenStar™ 3 2630 Display takes variable-rate application to the next level with a large color display for viewing and creating maps. The GreenStar 3 2630 Display also works with approved (ISOBUS-) rate controllers to enhance variable-rate application.

Variable rate technology allows input application rates to be varied across fields to specifically manage field variability. The variable-rate application reduces input usage and environmental impacts while increasing efficiency and providing economic benefits. An example would be applying fertilizer to areas with high yield potential and reducing the amount of fertilizer in areas where nutrients are more likely to be washed out.

There is an increasing need and requirement to document the production process from field preparation to crop harvest. Precise documentation capabilities are provided by the GreenStar™ 3 2630 Display.

On-screen mapping provides in-cab visualization in color and, by color-coding each pass on a map, the display provides a real-time picture of the crop harvested or rates applied when spraying, spreading, or planting. Apex™ software or compatible desktop software helps optimize business through more informed decision making while also meeting regulation requirements.

A task can be planned on the desktop software and transferred to the display. Field operations are recorded and stored. The data can then be transferred from the display, using a flash drive, to the desktop software for job reporting and analysis. This means less paperwork and more focus on analysis.

The documentation functionality provides data collection tools to document the farming operation. Features include:

- On-screen mapping

- Jobs

- Variable-rate applications

- As-applied map

- Coverage map

- Markers

- Conditions (soil and weather)

Data collected on the display via these functionalities are providing a solid basis for precise, complete, and easy documentation.

A variety of John Deere precision applications can be run on the GreenStar™ 3 (GS3) 2630 Display with a StarFire™ 6000 or StarFire 3000 Receiver regardless if it is planting or harvesting season, or for any application in between.

One single display and receiver can increase an operation’s productivity and provide a consistent operating experience.

The following activations can be purchased and unlocked on the display with a 24-digit activation code:

- AutoTrac™ assisted steering system increases productivity, reduces input costs, and leaves an operator with more energy. The GS3 2630 Display coupled with AutoTrac activation can provide automatic guidance with integrated AutoTrac, AutoTrac Controller, or AutoTrac Universal.

- AutoTrac RowSense guidance system provides the best in automatic guidance by pairing up row feeler data with satellite positioning data when harvesting row crops with a combine or John Deere self- propelled forage harvester.

- Pivot Pro brings all the benefits of AutoTrac to applications needing automated tracking in circle mode.

- John Deere Section Control reduces input cost by automatically turning implement sections off in previously covered areas and turning them back on precisely to decrease skips.

- iTEC™ Pro system automates end-row functions to reduce operator stress and increase efficiency while consistently managing headland space.

- John Deere Machine Sync system provides combine harvest automation, harvest logistics, coverage map sharing, and guidance line sharing functionality.

- Surface Water Pro Plus™ system offers the additional benefits of advanced ditching.

Additional applications for the GS3 2630 Display and StarFire receivers

These applications do not require a separate activation for the display:

- John Deere Active Implement Guidance keeps the implement and the tractor on the same guidance line to achieve optimal input placement.

- iGrade™ leveling system offers automated land leveling

- John Deere mobile weather

- John Deere Harvest ID, Cotton

- John Deere Rate Controller

- John Deere Rate Controller, Dry

GS3 demo activations

There are 15-hour demo activations available for the GS3 2630 Display. The following activations are available for demonstrations:

- AutoTrac

- AutoTrac RowSense™

- Pivot Pro

- John Deere Section Control

- iTEC™ Pro system

- Surface Water Pro Plus

Start with SF1, SF2, SF3, Radio RTK, or Mobile RTK

Start with SF1, SF2, SF3, Radio RTK, or Mobile RTK Support a variety of applications

Support a variety of applicationsUpgrades

John Deere precision agricultural technology provides multiple opportunities to upgrade. Producers can confidently invest in technology today, knowing it can grow and change as their operations do. Producers can contact a John Deere dealer to learn more about available solutions.

Software upgrade

Producers have the ability to upgrade signal accuracy with activations on the receiver only and no need to update AutoTrac™ assisted steering system display activation.

John Deere dealers offer an upgrade option for all AMS software applications from a previous to newer model.

Hardware upgrade

Producers also have the ability to upgrade to the latest displays and receivers.

Upgrade to:

- GreenStar 3 Display

- StarFire™ 6000 or 3000 Receiver

Maximizing investment cost

Many of the same solutions available with AutoTrac are compatible with the GreenStar system using AutoTrac Controller or AutoTrac Universal. Additional solutions available include John Deere Active Implement Guidance, John Deere Section Control, and the GreenStar Rate Controller.

This provides many options with one constant: stretching the producer’s money to bring more optimization to all equipment.

Producers will need to determine what:

- Display and receiver meets each machine’s needs

- Displays and receivers meet the operation's need today and in the future

GreenStar display sample options

Use existing GreenStar display and move display between machines throughout the cropping cycle:

- GreenStar 3 2630 Display

- GreenStar 2 1800 Display

Upgrade to a new display, trade in existing display

- Transfer activations within GreenStar 2 Display (GreenStar 2 2600 or GreenStar 2 1800 Display)

- Upgrade activations to a GreenStar 3 Display (GreenStar 3 2630 Display)

Add a new display

This allows each machine to have a dedicated display and eliminates the need to move a display from machine to machine.

- GreenStar 3 2630 Display

- GreenStar 2 1800 Display

Receiver options

Use an existing StarFire receiver and move it between machines throughout the cropping cycle

- StarFire 6000 Receiver

- StarFire 3000 Receiver

Add a new receiver

- This allows each machine to have a dedicated receiver and eliminates the need to move a receiver from machine to machine

All producers, whether new to precision technology or an experienced user, are invited to visit a John Deere dealer to customize the right precision solution package that meets needs now and in the future.

Leverage common components from JDLink Connect to enable wireless transfer of setup files and documentation data as well as remote monitoring and support.

Common components

Common components

To use RDA or WDT, the following components are required:

- GreenStar™ 3 2630 Display for RDA or WDT or Generation 4 CommandCenter™ Display for RDA or WDT

- Ethernet cable

- Computer or mobile device with internet connection

- Updated display software version

- Active JDLink Connect subscription

As the number of precision ag products continues to increase, more technology becomes integrated into ag equipment. Managers need the ability to send data and provide remote support for operators with varying skill level.

From any internet-connected device, managers can view exactly what the operator sees on the GreenStar 3 2630 Display and Generation 4 CommandCenter. Managers can also send setup information and receive documentation files in the Operations Center from most internet-connected devices.

Learn more at the following links:

Specifications

Accessories and Attachments

Ag Management Solutions

This product is similar to the protective film used on hand-held touchscreen electronics and can reduce screen damage from regular use. It includes all necessary instructions and tools to install the transparent film over a touchscreen display.

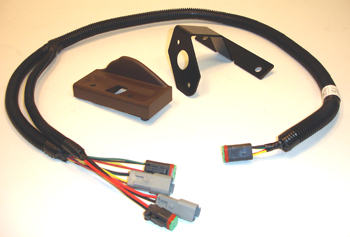

GreenStar 2 vehicle connector

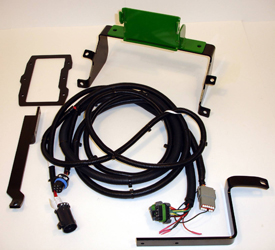

GreenStar 2 vehicle connectorAtu Supplemental Kits

Autotrac Integrated Machine Kits

Machines must be GreenStar™ ready to be compatible with the AutoTrac machine kits. AutoTrac machine kits include the appropriate machine steering controller when necessary and AutoTrac-ready accessories. Display, receiver, and software to complete system sold separately.

Machines must be GreenStar™ ready to be compatible with the AutoTrac machine kits. AutoTrac machine kits include the appropriate machine steering controller when necessary and AutoTrac-ready accessories. Display, receiver, and software to complete system sold separately.

Combine vehicle kit for 70 Series

Combine vehicle kit for 70 SeriesAutoTrac Electrical Connector Assembly - 7020 or 7015 Models - PF90495

AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit  AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4710 models AutoTrac sprayer vehicle kit for 4720 models

AutoTrac sprayer vehicle kit for 4720 models AutoTrac sprayer vehicle kit

AutoTrac sprayer vehicle kit AutoTrac sprayer vehicle kit for 4920 models

AutoTrac sprayer vehicle kit for 4920 modelsAutoTrac Sprayer Machine Kit - 4920 Models (PIN 003999 and below) - PF90811

AutoTrac Tractor Base Kit - 6110M, 6120M, 6130M, 6135M, 6145M, 6155M, 6175M, 6195M - BPF10996

AutoTrac Tractor Hydraulic Kit - 6110M, 6120M, 6130M - BPF11426

AutoTrac Tractor Hydraulic Kit - 6135M, 6145M - BPF10997

AutoTrac Tractor Hydraulic Kit - 6155M - BPF11257

AutoTrac Tractor Hydraulic Kit - 6175M, 6195M - BPF11258

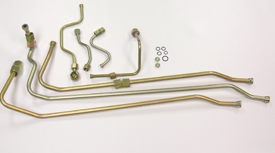

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

- GreenStar 3 (GreenStar3) 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or RTK

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

- GreenStar 3 (GreenStar3) 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or RTK

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

- GreenStar 3 (GreenStar3) 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or RTK

AutoTrac Tractor Machine Kit - 6110R, 6120R, 6130R (FT4) with MFWD - BPF10989

AutoTrac Tractor Machine Kit - 6135R model with MFWD - BPF10987

AutoTrac field-installed kits are now available for 6105R, 6115R, 6125R, 6140R, or 6150R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors and are compatible with the GreenStar™ 3 or GreenStar 2 system components.

These kits contain all of the required hydraulic components and harnesses for field installation.

GreenStar display options:

- GreenStar 3 (GreenStar3) 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or RTK

AutoTrac Tractor Machine Kit - 6145R, 6155R models with MFWD - BPF10985

AutoTrac field-installed kits are now available for 6210R, 6190R, and 6170R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors.

All required hydraulic components and harnesses for field installation are contained in these kits.

GreenStar™ display options:

- GreenStar 3 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or Real Time Kinematic (RTK)

The AutoTrac system reduces overlap, saving time, fuel, and labor costs. Whether breaking stubble with tillage equipment, planting or seeding, spraying or fertilizing, it reduces implement overlap by up to 90 percent. It also provides faster headland turns because the AutoTrac system takes the guesswork out of the return path.

AutoTrac Tractor Machine Kit - 6420 Models with mechanical front-wheel drive (MFWD) - PF90568

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit items AutoTrac tractor vehicle kit items

AutoTrac tractor vehicle kit items More AutoTrac tractor vehicle kit items

More AutoTrac tractor vehicle kit itemsWhen paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

AutoTrac Tractor Machine Kit - 8000T Series - PF90396

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit  AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit  AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit  AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

AutoTrac tractor vehicle kit

AutoTrac tractor vehicle kit AutoTrac Tractor Machine Kit - 9030 Series Wheel Scraper Tractor - PF90849

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

When paired with a StarFire™ receiver and GreenStar™ display, the integrated AutoTrac™ machine kit completes the components that automatically steer the machine. This kit is tied directly into the steering system on the machine and, therefore, provides optimum accuracy. The steering kit components cannot be moved across machine platforms.

Key features of the integrated AutoTrac steering kit:

- Integration, for a clean look in the machine

- Uses GreenStar components and AutoTrac software

- Works with the Original, GreenStar 2, or GreenStar 3 systems

- Uses SF1, SF2, or Real Time Kinematic (RTK) satellite signal

AutoTrac Tractor Wheel Angle Sensor - 6110M, 6120M, 6130M, 6135M, 6145M, 6155M, 6175M, 6195M - BPF11239

AutoTrac and GreenStar Ready Field Kit - Hagie Sprayers - BPF11531

AutoTrac sprayer vehicle kit for 4710 models

AutoTrac sprayer vehicle kit for 4710 models  AutoTrac SPFH base kit for ProDrive transmissions

AutoTrac SPFH base kit for ProDrive transmissionsAutotrac Universal Supplemental Kits

ATU Supplemental Kit - 5R Tractor - BPF11540

AutoTrac Supplemental Steering Kit - "AC" - BPF11275

Connectors

Connectors Auxiliary resume switch

Auxiliary resume switchThe AutoTrac™ Universal (ATU) auxiliary resume switch enables the ATU unit to be engaged from a remote location in the cab or operator's station.

The switch can either be mounted directly to a rigid surface or disassembled to allow panel mounting.

By installing this switch, operators can engage the ATU system in a location that provides them easy access and is convenient for all their applications throughout the growing season.

NOTE: This attachment is orderable through the AMS Price Pages as part number PF90453.

AutoTrac Universal horn kit

AutoTrac Universal horn kit AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

AutoTrac™ is an assisted hands-free steering system that automatically steers the machine through the fields. For some of the competitive sprayers, an AutoTrac Universal Hub will be required along with other attachments. For complete compatibility information, see the ATU look up tool.

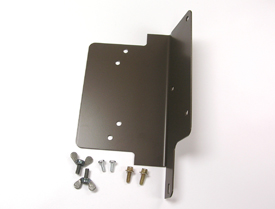

Original Greenstar display slotted bracket

Original Greenstar display slotted bracketAutoTrac Universal Steering Supplemental Kit - "AA" - BPF11130

AutoTrac Universal Steering Supplemental Kit - "Y" - BPF10791

AutoTrac Universal Steering Supplemental Kit - B - PF90518

AutoTrac Universal Steering Supplemental Kit - C - PF90510

AutoTrac Universal Steering Supplemental Kit - Case CS Row Crop Tractor - BPF11795

AutoTrac Universal Steering Supplemental Kit - D - PF90437

AutoTrac Universal Steering Supplemental Kit - E - PF90451

AutoTrac Universal Steering Supplemental Kit - F - PF90448

AutoTrac Universal Steering Supplemental Kit - G - PF90454

AutoTrac Universal Steering Supplemental Kit - H - Case Magnum - PF90455

AutoTrac Universal Steering Supplemental Kit - I - Case IH Steiger - PF90466

AutoTrac Universal Steering Supplemental Kit - J - BPF11794

AutoTrac Universal Steering Supplemental Kit - K - PF90464

AutoTrac Universal Steering Supplemental Kit - L - PF90468

AutoTrac Universal Steering Supplemental Kit - M - Claas Lexion/Jaguar - PF90512

AutoTrac Universal Steering Supplemental Kit - N - Claas Lexion - PF90504

AutoTrac Universal Steering Supplemental Kit - O - PF90544

AutoTrac Universal Steering Supplemental Kit - P - PF90470

AutoTrac Universal Steering Supplemental Kit - Q - PF90548

AutoTrac Universal Steering Supplemental Kit - R - 6x10/6x50 SPFH - PF90557

AutoTrac Universal Steering Supplemental Kit - S - PF90608

AutoTrac Universal Steering Supplemental Kit - T - PF90609

AutoTrac Universal Steering Supplemental Kit - U - PF90509

AutoTrac Universal Steering Supplemental Kit - V - PF90547

AutoTrac Universal Steering Supplemental Kit - W - PF90890

AutoTrac Universal Steering Supplemental Kit - X - PF90889

AutoTrac Universal Steering Supplemental Kit Z - BPF10848

FT4 GreenStar Harness - BPF11129

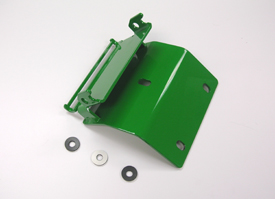

Greenstar Brackets

Combine StarFire position receiver bracket

Combine StarFire position receiver bracket Position receiver bracket

Position receiver bracket Deluxe Shroud Conversion Bracket Kit - PF91010

Deluxe Shroud Conversion Bracket Kit - PF91009

Deluxe Shroud Conversion Bracket Kit - 6020 or 6030 Series or Small Frame 7000, 10, 20, or 30 Series Tractors - PF90780

Deluxe Shroud Conversion Bracket Kit - RTK Base Station and Tripod - PF90781

GreenStar Display Cornerpost Bracket - S-Series Combines - BPF11186

GreenStar Tractor Bracket Bundle - 6B Tractors - BPF11167

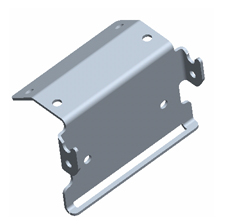

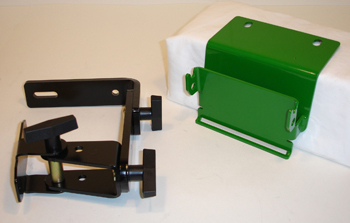

GreenStar tractor bracket kit

GreenStar tractor bracket kit  GreenStar tractor bracket kit

GreenStar tractor bracket kit GreenStar Tractor Bracket Kit - 9020 Series - PF90409

GreenStar Tractor Bracket Kit - 9020 Wheel or 9020 Track Series - PF90199

GreenStar Tractor Harness Bundle - 6B Tractors - BPF11184

John Deere AutoTrac Controller Bracket - BPF10472

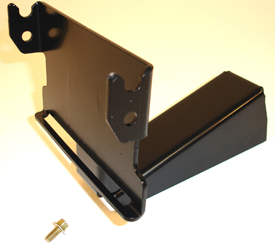

Mounting kit for GreenStar 2 display

Mounting kit for GreenStar 2 display  Mounting kit for GreenStar 2 display control unit

Mounting kit for GreenStar 2 display control unit Position receiver bracket and connector kit

Position receiver bracket and connector kit Position receiver bracket

Position receiver bracket Shroud mount

Shroud mountStarFire Receiver Bracket Bundle - BPF11185

StarFire Receiver Bracket Kit - (MY13-MY16) 6M Tractors - BPF11274

StarFire Receiver Deluxe shroud

StarFire Receiver Deluxe shroudStarFire Receiver Universal Mounting Bar Kit - BPF11356

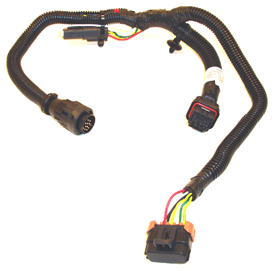

Greenstar Harnesses

AutoTrac Universal 300 Adapter Harness - BPF11855

AutoTrac Universal 300 Main Harness Installation Kit - BPF11849

GreenStar Cab Roof Harness - 6110M, 6120M, 6130M, 6135M, 6145M, 6155M, 6175M, 6195M - BPF10995

GreenStar Harness Kit for Non-GreenStar Ready Machines and Open Operator Stations - BPF11850

GreenStar Mobile Guidance Kit - John Deere or Competitive Models - BPF10302

GreenStar Power Harness - 6110M, 6120M, 6130M, 6135M, 6145M, 6155M, 6175M, 6195M - BPF10994

GreenStar RS232 Harness Kit for Third-Party Displays - BPF11859

GreenStar Ready Harness Kit - 6M (MY16) FT4 Cab - BPF11333

GreenStar Ready Universal Guidance Kit, Upgradeable - John Deere or Competitive Models - BPF10139

GreenStar 2 third-party controller kit

GreenStar 2 third-party controller kit  GreenStar 2 vehicle connector

GreenStar 2 vehicle connector Harness for Field Doc Connect

Harness for Field Doc Connect GreenStar ISO implement

GreenStar ISO implement GreenStar desktop bundle

GreenStar desktop bundle 35-ft extension harness

35-ft extension harness GreenStar 2 to Orginal GreenStar vehicle connector harness

GreenStar 2 to Orginal GreenStar vehicle connector harnessGreenstar Implement Control Kits

Active Implement Guidance Closed Center Valve - BPF10383

Active Implement Guidance Counterbalance Valve - BPF10548

Active Implement Guidance External Selective Control Valve (SCV) Switch and Harness Kit - BPF10356

Active Implement Guidance External Valve Bracket Kit - BPF10352

Active Implement Guidance Implement Feedback Harness (4 m) - BPF10032

Active Implement Guidance Implement Feedback Harness Extension (9 m) - BPF10019

Machine specific kits provide dealers with all of the hardware and harnessing to equip your 2410C or 2510H with dry applicator with AccuFlow Vortex Cooler minus:

- EVA hose

- Vapor hose

- Nurse tank hose

- GreenStar Rate Controller

Active Implement Guidance Open Center Valve - BPF10382

Auxiliary-power extension harness

Auxiliary-power extension harnessBracket Assembly - John Deere 2510 Series Applicators - PF90826

CAN Front Extension Harness (12 m) - PF90553

Center extension harness

Center extension harness Center extension harness

Center extension harnessFront Extension Harness (10 m) - BPF11284

Front Extension Harness (3 m) - BPF11285

High-current power-adapter harness

High-current power-adapter harness High-current power-adapter harness

High-current power-adapter harness High-current power-extension harness

High-current power-extension harnessHigh Current Power Extension Harness (3 m) - PF90825

Implement Mast - For universal use on 177.8-mm or 203.2-mm (7-in. or 8-in.) Frame Tubes - PF90524

Implement Mast - John Deere CCS Planter With Refuge Plus Tank (MY2006 and newer) - PF90549

Implement Mast - John Deere CCS Planter without Refuge Plus Tank (MY2004 and newer) - PF90525

Implement Receiver Harness - PF90538

John Deere Application Controller Mounting Hardware - 6R FT4 - BPF11686

John Deere Application Controller Mounting Hardware - 7R - BPF10732

John Deere Application Controller Mounting Hardware - 8000, 8010 and 8R Wheeled Series Tractors - BPF10041

John Deere Application Controller Mounting Hardware - 8000T and 8010T Series Tractors - BPF10020

John Deere Application Controller Mounting Hardware - 8020 Wheeled Series Tractors - BPF10022

John Deere Application Controller Mounting Hardware - 8020T Series Tractors - BPF10021

John Deere Application Controller Mounting Hardware - 8RT Series Tractors - BPF10042

John Deere Application Controller Mounting Hardware - 9000 and 9020 Wheeled and Track Series - BPF10023

John Deere Application Controller Mounting Hardware - 9R - BPF10731

John Deere Application Controller Mounting Hardware - 9R, 9RT - BPF11173

Switch and power extension harness

Switch and power extension harnessPower Harness - Four-wheel drive (4WD) Tractor - BPF10404

Power Harness - Row Crop Tractor - BPF10403

Rear extension harness

Rear extension harnessiGrade Counterbalance Valve - BPF10547

iGrade or Active Implement Guidance Implement CAN Extension Harness - BPF10018

Surface water implement mast

Surface water implement mast  Surface Water Pro receiver mounting kit

Surface Water Pro receiver mounting kit Greenstar Miscellaneous Hardware

Ethernet switch

Ethernet switch

The Ethernet switch enables connectivity for a GreenStar™ 3 2630 Display and a Generation 4 CommandCenter™ to the modular telematics gateway (MTG) to support MyJohnDeere applications. The Ethernet switch has five M12 Ethernet connectors and one M12 power connector.

Greenstar Rate Controller Kits

Rate controller NH3 adapter harness

Rate controller NH3 adapter harness Rate Controller CCS drill clutch adapter harness

Rate Controller CCS drill clutch adapter harness Rate controller HARDI adapter harness

Rate controller HARDI adapter harness Implement height sensor

Implement height sensor Rate-controller-implement height-sensor bracket

Rate-controller-implement height-sensor bracket Rate Controller In-Cab Front Extension Harness Installation Kit - BPF10044

Half-width adapter harness for KINZE planters

Half-width adapter harness for KINZE planters Liquid fertilizer adapter harness

Liquid fertilizer adapter harness Rate controller planter clutch half-width adapter

Rate controller planter clutch half-width adapter Rate controller pull-type sprayer adapter harness

Rate controller pull-type sprayer adapter harness Optional switchbox

Optional switchbox An optional switchbox can be added for manual control of individual boom sections.

The switchbox comes with a bracket and hardware, and it can be mounted above or below the display.

Greenstar Ready Machine Kits

GreenStar-ready guidance kit

GreenStar-ready guidance kit  GreenStar-ready sprayer kit

GreenStar-ready sprayer kit

Following are the parts included in the kit.

| PF11098 | Bracket (subassembly for GPS bar) |

| PF11097 | Bracket for GPS bar |

| PF80722 | Harness, StarFire™ rooftop bulkhead adapter |

| PF80802 | Harness, cab |

| PF80818 | Harness, 19-pin bulkhead to GSD/GSD/MP for dual GSDs |

| RE175036 | Bracket (quick-coupler assembly) |

| R185095 | Bracket, monitor |

| R237730 | Bracket, monitor mount |

| R244202 | Bracket, monitor mount |

| PF12400 | Strap, slotted |

| PF80502 | GPS mounting bar sssembly |

| PF80505 | Hardware assembly, GPS bar |

| RE43542 | Diode, transient voltage protection |

| RE171663 | PTC power adapter |

| RE171664 | PTC junction box |

GreenStar-ready TECU conversion tractor kit

GreenStar-ready TECU conversion tractor kitGreenStar Ready TECU Conversion Tractor Kit - 6030 or 7030 Premium Series (MY2008 and newer) - PF91089

GreenStar-ready TECU conversion tractor kit

GreenStar-ready TECU conversion tractor kit  GreenStar-ready TECU harness conversion kit

GreenStar-ready TECU harness conversion kit  GreenStar-ready tractor kit, 6020 or 7020 series

GreenStar-ready tractor kit, 6020 or 7020 series AutoTrac field-installed kits are now available for 6210R, 6190R, and 6170R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors.

All required hydraulic components and harnesses for field installation are contained in these kits.

GreenStar™ display options:

- GreenStar 3 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or Real Time Kinematic (RTK)

AutoTrac field-installed kits are now available for 6210R, 6190R, and 6170R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors.

All required hydraulic components and harnesses for field installation are contained in these kits.

GreenStar™ display options:

- GreenStar 3 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or Real Time Kinematic (RTK)

AutoTrac field-installed kits are now available for 6210R, 6190R, and 6170R MFWD Tractors.

These field-installed kits are an integrated guidance solution for John Deere 6R MFWD Tractors.

All required hydraulic components and harnesses for field installation are contained in these kits.

GreenStar™ display options:

- GreenStar 3 2630 and CommandCenter™

- AutoTrac activation for GreenStar 3

- GreenStar 2 1800

- AutoTrac activation for GreenStar 2

StarFire™ Receiver and signal options:

- StarFire 3000

- SF1, SF2 activation, or Real Time Kinematic (RTK)

The AutoTrac system reduces overlap, saving time, fuel, and labor costs. Whether breaking stubble with tillage equipment, planting or seeding, spraying or fertilizing, it reduces implement overlap by up to 90 percent. It also provides faster headland turns because the AutoTrac system takes the guesswork out of the return path.

GreenStar-ready tractor kit, 7000 or 7010 Series

GreenStar-ready tractor kit, 7000 or 7010 Series GreenStar Ready Tractor Kit - 8000, 8010 or 8020 Series - PF90252

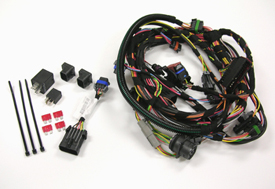

High-current power harness

High-current power harness

For applications/implements requiring more than 60 amperages power.

- The high-current power harness provides an add-on harness for John Deere 8000, 8010, 8020, 9000, or 9020 Tractors currently GreenStar™ (GS) ready that require power capabilities in excess of 60 amps.

- For non GS ready 8000, 8010, 8020, 9000, or 9020 Tractors, the GS ready tractor kit provides a single harness solution providing high current and GS ready capabilities.

GS-ready tractor kit for 9000 or 9020 Series

GS-ready tractor kit for 9000 or 9020 Series  High-current power harness

High-current power harness

For applications/implements requiring more than 60 amperages power.

- The high-current power harness provides an add-on harness for John Deere 8000, 8010, 8020, 9000, or 9020 Tractors currently GreenStar™ (GS) ready that require power capabilities in excess of 60 amps.

- For non GS ready 8000, 8010, 8020, 9000, or 9020 Tractors, the GS ready tractor kit provides a single harness solution providing high current and GS ready capabilities.

GreenStar-ready tractor kit

GreenStar-ready tractor kit  GreenStar-ready tractor kit

GreenStar-ready tractor kit The AutoTrac system reduces overlap, saving time, fuel, and labor costs. Whether breaking stubble with tillage equipment, planting or seeding, spraying or fertilizing, it reduces implement overlap by up to 90 percent. It also provides faster headland turns because the AutoTrac system takes the guesswork out of the return path.

The AutoTrac system reduces overlap, saving time, fuel, and labor costs. Whether breaking stubble with tillage equipment, planting or seeding, spraying or fertilizing, it reduces implement overlap by up to 90 percent. It also provides faster headland turns because the AutoTrac system takes the guesswork out of the return path.

High-current power harness

High-current power harness

For applications/implements requiring more than 60 amperages power.

- The high-current power harness provides an add-on harness for John Deere 8000, 8010, 8020, 9000, or 9020 Tractors currently GreenStar™ (GS) ready that require power capabilities in excess of 60 amps.

- For non GS ready 8000, 8010, 8020, 9000, or 9020 Tractors, the GS ready tractor kit provides a single harness solution providing high current and GS ready capabilities.

High-current power harness

High-current power harness

For applications/implements requiring more than 60 amperages power.

- The high-current power harness provides an add-on harness for John Deere 8000, 8010, 8020, 9000, or 9020 Tractors currently GreenStar™ (GS) ready that require power capabilities in excess of 60 amps.

- For non GS ready 8000, 8010, 8020, 9000, or 9020 Tractors, the GS ready tractor kit provides a single harness solution providing high current and GS ready capabilities.

Harvest Sensor Kits

Moisture sensor conversion kit

Moisture sensor conversion kit  Combine moisture sensor retrofit kit on 50 Series

Combine moisture sensor retrofit kit on 50 SeriesFirst introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

First introduced in 1995, Combine Yield Monitoring and Combine Yield Mapping were John Deere’s first precision farming products. It is capable of monitoring or mapping yield and moisture on many of the older John Deere combines as field-installed attachments.

Harvest Monitor™ and Harvest Doc™ – 9060 Series Combines

*Harvest Monitor and Harvest Doc is retrofittable to 50 Series Combines

Functionality includes multi-client functionality, boundary recording, and weather and field condition recording as well as compatibility to GreenStar™ guidance products.

Harvest Monitor enables the operator to view yield and moisture while harvesting. It consists of the following components:

- Grain tank-mounted moisture sensor

- Mass flow sensor

- GreenStar display

- Associated brackets and harnesses

Harvest Doc enables the operator to record yield and moisture with GPS and later load the information into desktop software as maps and reports. To upgrade from Harvest Monitor to Harvest Doc, the following additional components are necessary:

StarFire™ Receiver

- Apex™ desktop software

- GreenStar display

Today’s producers demand more and with GreenStar™ technology and John Deere delivers. With GreenStar components, customers have the ability to document and map harvest data, create prescriptions, set field boundaries and more. This translates to better management practices, better yields, and more profit.

Harvest Doc Cotton

The Harvest Doc Cotton yield mapping system from John Deere Ag Management Solutions (AMS) gives cotton producers the ability to see harvest data right from the cab. Using yield data collected by the machine, detailed cotton yield maps can be generated in Apex™ Farm Management software to help producers make more informed decisions.

Harvest Doc Cotton-ready machines are equipped with mass-flow sensors that monitor cotton flow through the machine’s air ducts. This information is then sent to the display in the cab for operator viewing.

Machine compatibility:

- Both the 7760 and 7660 Cotton Pickers are Harvest Doc Cotton ready, straight from the factory.

- The 7460 Cotton Stripper is available with a field-installed attachment to make it Harvest Doc Cotton ready.

For Harvest Doc Cotton functionality, the following GreenStar components are also needed:

- StarFire™ 3000 or StarFire™ iTC receiver

- GreenStar 3 2630 or GreenStar 2 2600 Display

- Data card or universal serial bus (USB) drive

NOTE: Harvest Doc Cotton-ready machines are equipped with mass-flow sensors and associated brackets, cab signal combiner module (SCM), StarFire receiver bracket, GreenStar 2/GreenStar 3 mounting bracket, and lightbar adapter harness.

GreenStar displays

The GreenStar 3 2630 Display provides the operator with a number of items, including lint yield, load weight, GPS and recording status, cotton variety, area, and distance covered. All of this information can be compiled within the Harvest Doc Cotton system.

The GreenStar 3 2630 Display is fully compatible with both the 7760 and 7660.

StarFire receivers

StarFire receivers help producers track in-field productivity using GPS and GLONASS satellite signals.

In Harvest Doc Cotton, StarFire receivers' georeference yield data is captured by the mass flow sensors. This information is transferred to the cab display, which can then give operators yield data relative to field position.

To accommodate a wide range of accuracy needs and to offer unmatched upgradeability, the StarFire 3000 Receiver is available in different configurations: SF1 and SF2 ready.

Apex Farm Management software

In the office, Apex Farm Management software is used to generate detailed yield data.

The cotton yield map from Apex shows yield variance throughout the field. Also, printed on the map is the total number of acres harvested, harvest date, average yield, and harvest hours for the operator, farm, and field.

Machine Control

Combine Hydro Handle for Machine Sync Application - BPF10405

John Deere Machine Sync 3/4 Bin Fill Kit - 70 Series Combine (MY2008 or MY2009) - BPF10504

Miscellaneous

GreenStar combine bracket kit

GreenStar combine bracket kit  AutoTrac SPFH base kit for non-ProDrive

AutoTrac SPFH base kit for non-ProDrive AutoTrac SPFH controller for 7000 and 7050 Series

AutoTrac SPFH controller for 7000 and 7050 Series